WE ARE MINSTA

Our products are designed with care and precision for farmers and those who make their living from the land. We understand the farmer’s hard work and dedication required to tend crops and livestock. Our tools are built to last through all weather and seasons, so you can focus on what matters most – nurturing the land and your livelihood.

WHAT WE DO

Manufacture and sell high-quality and ecologically friendly agricultural equipments

WHY IT WORKS

We strive to build the best rotation tiller machine that not only fits you’re budget but also enhances your farm operation, increases productivity and improves the environment

WHY WORK WITH US

We use quality materials and parts to manufacture our implements. They are durable, dependable, and high performance.

ADVANTAGES

Skillful Team

Crop residue management, Land preparation and sowing operations possible

in a single pass which saves time and cost compare to other methods

Quality Assurance

Our team is committed to ensuring that all products are thoroughly checked and tested for quality to meet our client's expectations.

Conspicuous Position:

Our expertise and dedication have helped us attain a prominent role in the market, which sets us apart from our competitors.

Client Satisfaction:

We are dedicated to serving our clients in the best possible manner and aim to exceed their expectations with our quality products and exceptional customer service.

FAQ

Gearbox/transmission case Low oil level. Noise noticeable and constant Worn gears

?

Add oil to the gearbox/ transmission case

Intermittent Loose blades

?

Tighten blades hardware

noise from tiller Gear tooth damaged

?

Replace damaged gear

Noise and/or vibration Blades worn or damaged from tiller Bearings damaged

?

Replace blades and bearings

the front of the tiller is not leveled to the back

?

Adjust 3-point top link of tractor

making tiller PTO parallel to the ground

Rotor damaged

?

Repair/replace rotor

Hard soil

?

Reduce ground speed

Driveline vibration Worn driveshaft

?

Replace driveshaft

Machine lifted too high

?

Lower machine and readjust

tractors lift stop

Debris wrapped on rotor

?

Remove debris

Rotor stop turning Slip clutch slipping

?

Reduce load to tiller or

adjust slip clutch

Machine skip or leaves Badly worn blades

?

Replace worn blades

Crop residue Slip clutch slipping

?

Adjust slip clutch or reduce load

Ground speed too fast for conditions

?

Reduce ground speed

Smoke and/or hot smell Debris wrapped around in from tiller blades and/or rotor

?

Remove debris

Low oil level in gearbox

?

Add oil

Slip clutch slipping

?

Reduce load to machine or

adjust slip clutch

Gearbox overheating Low oil level

?

Add oil

Blades wear frequently Muddy or sandy soil

?

Reduce ground speed

Blades break frequently due to Stony soil

?

Reduce ground speed

Oil leaking from gearbox/ transmission case overfilled

?

Drain to proper level

Loose filling/drain plug

?

Tighten filling/drain plug

Damaged breather plug

?

Replace breather plug

Damaged seals

?

Replace seals

Tillage depth insufficient Tiller is carried by tractor. Tractor has insufficient

power

?

Lower tractor 3point arms,

increase PTO speed

Soil texture too coarse

?

A. Rear board too high. Lower rear board. B. PTO speed too slow. Increase PTO speed. C. Ground

speed

too

fast. Reduce ground speed

Soil texture too fine

?

Rear board too low. Raise rear board. b. Ground speed too slow. Increase ground speed

Tiller choking up with soil

?

Soil too wet. Wait until soil dries. Ground speed too fast. Reduce ground speed. Soil too hard.

Reduce

ground speed and make tilling in more steps

Tiller skipping on ground or leaving crop residue

?

Soil too hard. Reduce ground speed and make tilling in more steps

Tillage not uniform

?

Skids not aligned. Align skids. Tiller left side not leveled with Adjust tractor 3-point arms

Too much Load required to tractor

?

Excessive working depth. Lower skids. Excessive PTO speed. Reduce PTO speed

ROTARY TILLER RT SERIES

Model RT rotary tiller is characterized by a wide choice of available configurations. The structure allows to meet the requirements of small and medium-sized farms, achieving excellent results on even very difficult soils with considerable economy in the use of tractor power (up to 100 HP). Our rotary tillers also feature a sturdy gearbox that ensures smooth operation and minimal maintenance. They are easy to attach to tractors, making it possible for you to save time and reduce labor costs. The high-performance machine with a double sheet structure frame, multi-speed gearbox and the slip clutch PTO shaft allows the model RT to withstand strong stresses due to its coupling with tractors of up to 100 HP. The front depth wheels or tractor wheel eradicator system increases the working depth of rows, especially on narrow crop rows.

Performance

Sustainable

Accurate

DESCRIPTION

The MINSTA power tiller is designed for intensive soil loosening and breaking up of dirt clods. The work intensity depends on the rotor speed, tool type and forward travel speed. A general rule of thumb is the slower you work with the tiller, the quicker the rotor shaft turns, giving you a more fine and crumbled soil mixture. It’s important not to exaggerate this, as the soil’s natural crumble structure might be damaged.

CUT MATERIAL FOR BETTER SOIL STRUCTURE

The blades of Minsta rotary tillers provide exceptional cutting of plant material before working it into the soil for a better overall structure. Minsta rotary tillers can be used for: Cut plant debris including tree/vine prunings, incorporating mulch and cover plants into the soil, or plowing up a permanent vegetation cover.

LESS MAINTENANCE

The central gearbox provides no-hassle handling and maintenance. The semi-fluid grease eliminates the need for regular oil changes, and the slack adjuster ensures that you can work tilling immediately every time.

HIGH CLEARANCE

From clearing up to cultivating, our rotary tiller is the ultimate tool for working the ground. Its solid steel rotor shaft is fitted with high-quality steel blades designed to engage a variety of soils, while its rotor and hood design maximizes the efficiency of tractors to produce less drag so you don’t have to put extra power into your machine.

STANDARD POINTS

- Universal three point hitch, cat. II

- PTO shaft with slip clutch

- Side gears drive in oil bath

- Offset front bar hitches

- Oversized rotor Ø 560mm with high strength steel flanges

- 6 blades per flange (side blades are always mounted inwards)

- Adjustable Rear Deflector with Shockers/ Spring.

- Hardened-steel antiwear skids “Duo cone” waterproof sealings, oil bath lubrication

- New flanks for deeper tillage

- CE safety protections

- Slip Clutch – Standard 6 spline

- Tilling depth : 9″-10

WHY WE CHOOSE MINSTA

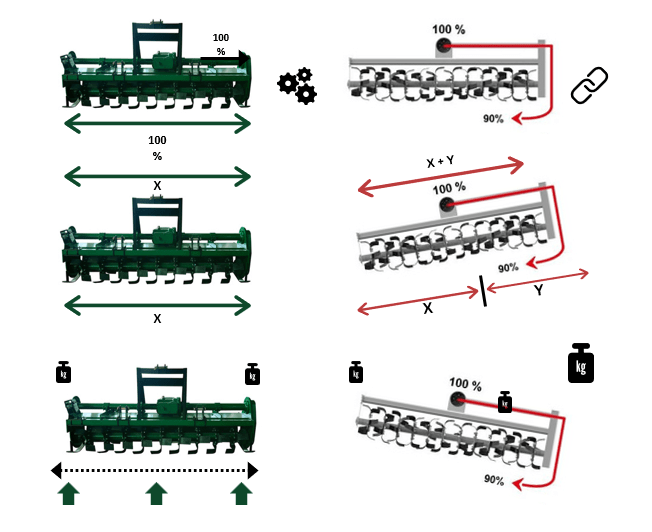

The rotating power is transmitted equally from the centre of the machine.This guarantees maximum reliability and low power absorption.

The working width of the machine is equivalent to the width of the gauge as there are side transmission guards.

The Minsta Transmission allows an optimal weight balance on both sides guards guarantees a constant tillage depth across the entire width.

Seals

Seals are an essential part of the product. Without them, no tiller can work on wet field. The waterproof mechanical seals consist of two metal rings opposite each other and separated by a thin film of oil. This ensures total isolation of the rotor bearings from mud, water and dust.

Three Gears

Model Rt rotary tiller is equipped with a three-gears side drive box that ensures constant transmission without loss of power.

TECHNICAL DATA

| MODEL | RT36 | RT48 | RT62 | RT84 | RT96 | RT108 |

|---|---|---|---|---|---|---|

| OVERALL LENGHT(MM) | 940 | 1350 | 1620 | 2230 | 2480 | 2860 |

| OVERALL HEIGHT(MM) | 800 | 900 | 900 | 1100 | 1100 | 1100 |

| TILLAGE LENGHT(MM) | 840 | 1250 | 1520 | 2100 | 2390 | 2770 |

| TILLAGE DEPT(MM) | 6" - 8" | 6" - 8" | 6" - 8" | 9" - 10" | 9" - 10" | 9" - 10" |

| 3 POINT HITCH TYPE | CAT - II | CAT - II | CAT - II | CAT - II | CAT - II | CAT - II |

| SIDE TRANSMISSION | GEAR DRIVE | GEAR DRIVE | GEAR DRIVE | GEAR DRIVE | GEAR DRIVE | GEAR DRIVE |

| GEAR BOX | SINGLESPEED | MULTISPEED 16 : 19 | MULTISPEED 16 : 19 | MULTISPEED 16 : 19 | MULTISPEED 16 : 19 | MULTISPEED 16 : 19 |

| PTO SHAFT | STANDARD 1 3/8' - 6 SPLINE | STANDARD 1 3/8' - 6 SPLINE | STANDARD 1 3/8' - 6 SPLINE | STANDARD 1 3/8' - 6 SPLINE | STANDARD 1 3/8' - 6 SPLINE | STANDARD 1 3/8' - 6 SPLINE |

| NO. OF BLADES | 16 | 24 | 36 | 54 | 54 | 66 |

| NO. OF DISC | - | - | 1 | 2 (optional) | 2 (optional) | 2 (optional) |

| WORKING POSITION | RIGID | RIGID | RIGID | RIGID | RIGID | RIGID |

| TRACTOR POWER REQUIRED | 15 - 20 | 20 - 25 | 25 - 30 | 40 - 90 | 70 or above | 80 or above |

| WEIGHT (KGS. APPROX) | 135 | 150 | 350 | 490 | 520 | 600 |

ROTO TERRA SEEDER

The Roto Terra Seeder machine is the combination of rotary tiller and seed drill. This attachment conforms to all applicable standard prescribed under Canadian farm vehicle Safety Regulations in effect on the date of manufacture.

Performance

Sustainable

Accurate

DESCRIPTION

Minsta Roto terra is the tractor operated Ultimate One Pass Sowing Solution Machine which removes the paddy stubbles and mixes it with soil, prepares land, and simultaneously sows seeds in row with proper spacing with seed quality and depth according to the field and crop worth smoothly and efficiently with heavy duty frame it improve soil quality and health. The seeder machine is the combination of rotary tiller and seed drill. This machine is a Semi Champion Plus rotary tiller with fitment of JF type blades in it, which ensures proper mixing of residues with soil effectively. Minsta seeder is an environment friendly and economical solution where farmers don’t need to burn crop residues and are not required to perform multiple operations on the field before sowing, hence it saves land from nutrients loss, saves time and cost for farmers.

LARGE HOPPER TANK

The hopper is equipped in two compartments to divide seeding and fertilizing, and also ensure correct and even flow of seed and fertilizer on steep slopes.

ADJUSTABLE DISPENSING OF THE SEED & FERTLIZER

The transport system is very simple and directly deposits the seeds & fertlizer between the working parts and the rear roller through a special adjustable rod to mix into the soil. The particular configuration of the machine uses tilting seed & fertlizer drop tubes.

STANDARD POINTS

- Universal three point hitch, cat. II

- PTO shaft with slip clutch

- Side gears drive in oil bath

- Offset front bar hitches

- Oversized rotor Ø 560mm with high strength steel flanges

- 6 blades per flange (side blades are always mounted inwards)

- Bonnet spring adjusters

- Hardened-steel antiwear skids “Duo cone” waterproof sealings, oil bath lubrication

- New flanks for deeper tillage

- CE safety protections

- Side transmission – Gear driven

- MULTISPEED – 13 : 23

- Seeding Till depth: 9”

Seals

Seals are an essential part of the product. Without them, no tiller can work on wet field. The waterproof mechanical seals consist of two metal rings opposite each other and separated by a thin film of oil. This ensures total isolation of the rotor bearings from mud, water and dust.

Three Gears

Model Rt rotary tiller is equipped with a three-gears side drive box that ensures constant transmission without loss of power.

TECHNICAL DATA

| MODEL / DESCRIPTION | RTS84 | RTS96 | RTS108 |

|---|---|---|---|

| OVERALL LENGHT(MM) | 2490 | 2794 | 2800 |

| OVERALL HEIGHT(MM) | 1372 | 1372 | 1372 |

| TILLAGE WIDTH(MM) | 2134 | 2438 | 2742 |

| 3 POINT HITCH TYPE | CAT - II | CAT - II | CAT - II |

| SIDE TRANSMISSION | GEAR DRIVE | GEAR DRIVE | GEAR DRIVE |

| GEAR BOX | MULTI SPEED 11 : 22 / 13 : 23 | MULTI SPEED 11 : 22 / 13 : 23 | MULTI SPEED 11 : 22 / 13 : 23 |

| SEED AND FERTILER MECH | Aluminum Fluted Roller Type | Aluminum Fluted Roller Type | Aluminum Fluted Roller Type |

| NO. OF BLADES | 54 | 60 | 66 |

| NO. OF DISC | 22 | 26 | 30 |

| NO. OF FURROR OPENER | 12 | 13 | 15 |

| TRACTOR POWER REQUIRED | 55 - 65 | 60 OR ABOVE | 65 OR ABOVE |

| WEIGHT (KGS. APPROX) | 1000 | 1050 | 1100 |